Cleanroom Project

Marya is a leading manufacturer and supplier of cleanroom systems, including consulting, design, and construction of cleanrooms; R&D, manufacturing, and transportation of cleanroom materials and equipment, as well as one-stop services of installation, verification, and after-sales. With over 20 years of industry experience, Marya can provide complete customized solutions for your specific needs and processes.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Why Choose Us

For the whole cleanroom project video, please click this link Video for Cleanroom Project

clean room window

clean room sliding door

As Chinese pharmaceutical cleanroom manufacturer and supplier, Marya can design and provide various cleanroom types. Such as cleanroom in pharmaceutical industry, hospital, medical device workshop, electronics workshop, aerospace, food processing industry, cosmetics, new energy, photovoltaic solar energy, animal laboratories, operating rooms etc. The following is the introduction of our cleanroom engineering advantages:

1. Our cleanroom cleanliness level is high(Class100-100000, ISO5-8, ClassA-D), the whole pharmaceutical cleanroom systems meet the requirements of GMP, FDA, WHO and other pharmaceutical standard, and our products far exceed other clean room companies;

2. Able to realize BMS automatic control;

3. Modular design, fast installation;

4. Construction material are CE certified;

5. High degree of safety, the important passages are equipped with safety doors, and the air duct system is designed and installed with fire dampers;

6. From A-Z, one-stop service, including design, manufacturing, construction, validation, training and after-sale service

7. Can accurately control the temperature, humidity, pressure difference, dust particles and the number of planktonic bacteria in the room, and cleanroom is constructed in strict accordance with the standards of different cleanliness levels in the GMP specification;

8. The brand of cleanroom HVAC system can be specified by customer;

9. Professional installation engineers with rich experience,able to send workers abroad for installation;

10.Clean room solutions: we have a strong design team with 20 years experience in clean room area, able to design according to customers' different needs and solve their difficulties and pain points;11.Engineering cases: Our professional team has built clean room projects for Pakistan, USA, Malta, Iran, UK, Indonesia, Tanzania and many other countries.

2. Marya Cleanroom Service Scope

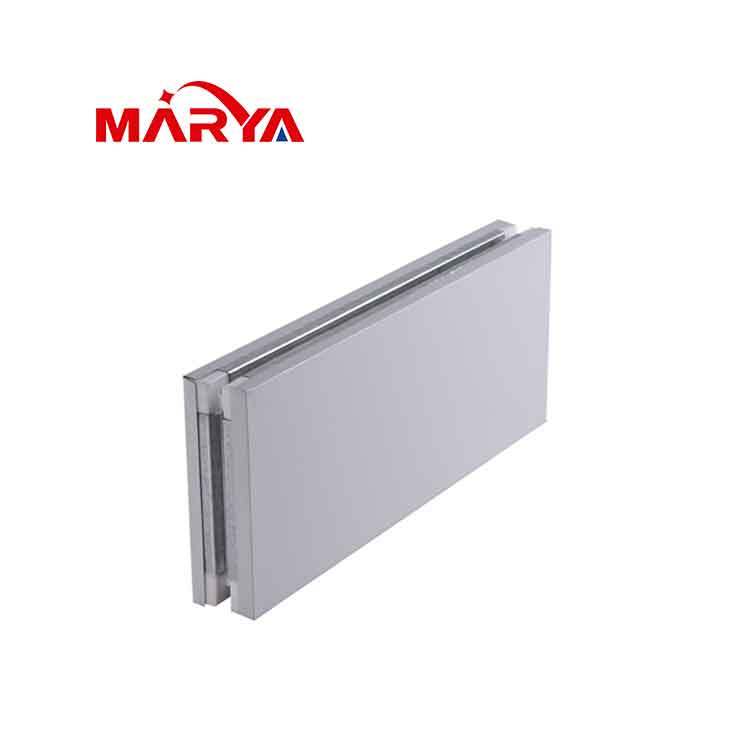

Cleanroom Project Scope(from structure, HVAC, electric to auto-control) 1. Cleanroom Structure: Wall Panel, Ceiling Panel, Windows, Doors, Lighting, Flooring, Fittings. 2. HVAC: AHU, Chiller, dehumidifier, Ducting, Piping, etc. 3. Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc. 4. Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel 5. Process Piping System: Gas, Water Pipeline Equipment Air shower, Cargo shower, Mist shower, Dynamic pass box, Static pass box, Sampling booth, Weighing booth, Dispensing booth, Medicine stability test chamber, isolator, VHP sterilizer, Biological safety chamber, FFU, LAF, etc. Temperature 21-27℃ (or as per required) Humidity 30-60℃ (or as per required) Application Pharmaceutical factory, hospital, medical device workshop, electronics workshop, food factory, cosmetics factory, etc. Qualification Documents DQ, IQ, OQ, PQ Full Service FAT and SAT Service, Professional Consultation, Training, User-friendly English Software, 24 hours technical support 3. Successful Cleanroom Project Case

We did a successful cleanroom project in Tanzania, click on the following link to learn more details: Tanzania Pharmaceutical Cleanroom Project

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

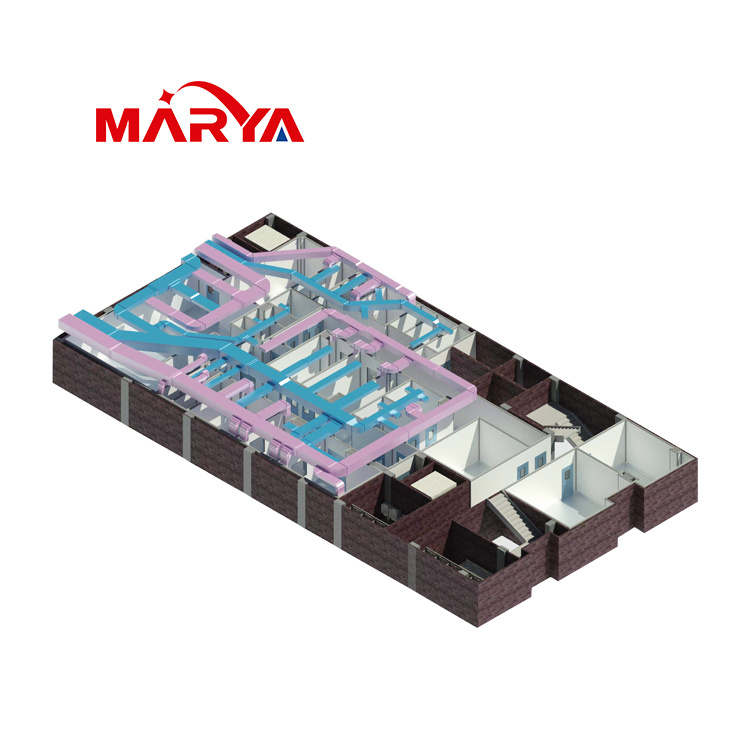

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

cleanroom project

cleanroom

Cleanroom manufacturer

Cleanroom Turnkey Project

Cleanroom Solution Provider

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131