-

Resource

-

-

Sterile Pharmaceutical Filling Line

-

Vial Filling Line

-

Syringe Filling Line

-

Cartridge Filling Line

-

RTU Container Filling Line

-

Ampoule Filling Line

View More -

-

Sterile Isolator System

View More -

Sterile Formulation System

-

SVP(Small Volume Parenteral)Preparation System

-

LVP(Large Volume Parenteral)Preparation System

-

CIP(Cleaning In Place)Station System

-

Stainless Vessel

View More -

-

Sterile Water Treatment System

-

Pharmaceutical Purified Water Generator

-

Pharmaceutical Water Distribution System

-

Pharmaceutical Water for Injection (WFI) Machine

-

Pharmaceutical Pure Steam Generator

View More -

-

Cleanroom System

View More -

Other Pharmaceutical Machinery

-

Solid Medicine Production Line

-

IV Fluid Production Line

-

Oral Liquid Production Line

-

Packaging Machine

-

Other Pharmaceutical Machinery

View More -

-

Injection Solution

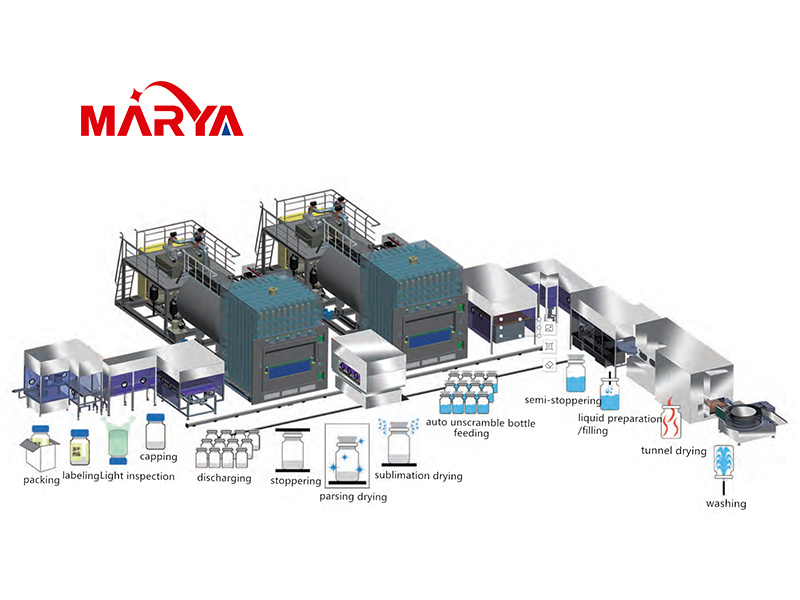

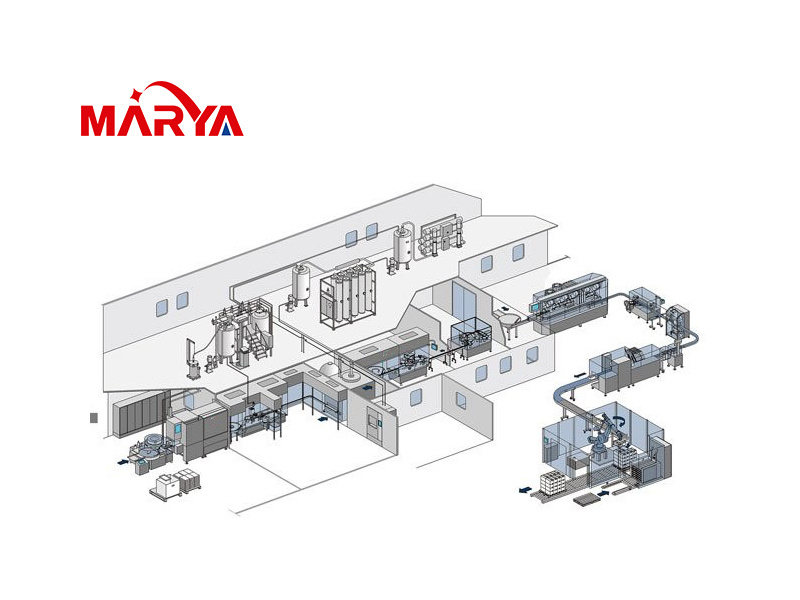

The application plan of the overall solution for aseptic small volume preparations specifically includes a series of fully automated production equipment and information management system for the production of sterile drugs such as vials of powder injection/fluid injection, ampoules, cartridges, pre-filling needle, BFS,etc, and it realized the deep integration of information technology and manufacturing technology, so as to creat a digital and intelligent manufacturing factory; this kind of equipment focus on the fields of high value-added biological drugs and anti-tumor drugs, etc, It has high flexibility and can meet the flexible production demands of batch drug production of pharmaceutical companies or the alternate production of multiple kinds of drugs.

(1) Core process system

The core process system mainly includes the sterilization system, filling system,liquid dispensing system, freeze-drying feeding and discharging system, rubber stopper cleaning sterilization system, aluminum cover cleaning system and other equipment and systems; and the filling system can be divided into the following types:

BFS production line

Ampoule filling production line

Vial powder injection production line

Vial liquid preparation production line

Pre-filling sealing production line

Cartridge filling production line

(2) Past packaging system

The past packaging system mainly includes lamp inspection/leak detection, labeling/blister/boxing, cartoning/palletizing and other packaging processes;

(3) Cleanroom system

The clean room system mainly includes architectural decoration, pipeline engineering, HVAC engineering and electrical engineering, etc;

(4) Utility

The utility mainly includes water treatment system, air condition unit, nitrogen production system, air pressure system, steam boiler and other equipment and systems;

Previous:

: Next

CONTACT

Shanghai Office: NO211, North Fute Road, Pudong area, Shanghai, China, 200131

Changsha Office: Room 23069, Block 6, Forte Star Shine World, Yuhua District, Changsha, Hunan province

Factory 1: No. 7, Building 1, No. 326 Linyu Road, Yuelu District, Changsha, Hunan, China

Factory 2: No 555, Yupan Road, Weitang Town, Xiangcheng District, Suzhou, Jiangsu Province, China

Factory 3: 15-A, Venture Capital Industrial Square, Yanghe Road, Suzhou Industrial Park