Biosafety cabinets

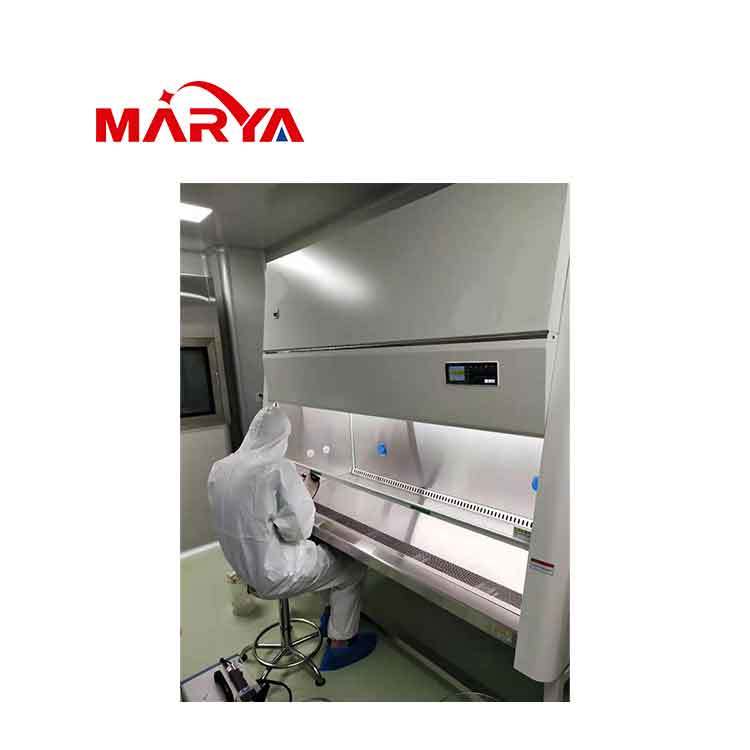

Biosafety cabinet (biological safety cabin.BSC) is a box type air purification negative pressure safety device which can prevent aerosol escape in some dangerous or unknown biological particles during experimental operation and treatment. It is widely used in microbiology, biomedicine, genetic engineering, biological products and other fields of scientific research, teaching, clinical testing and production, and is the most basic safety protection equipment in the first class protective barrier in laboratory biosafety.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Introduction

The working principle of the biosafety cabinet is to pump the air out of the cabinet to keep the negative pressure in the cabinet and protect the staff through vertical air flow. The air in the cabinet also needs to be filtered by HEPA filters to protect the environment.

2. Performance

- The 10° tilt angle design conforms to the ergonomic principle, and the operation experience is better;

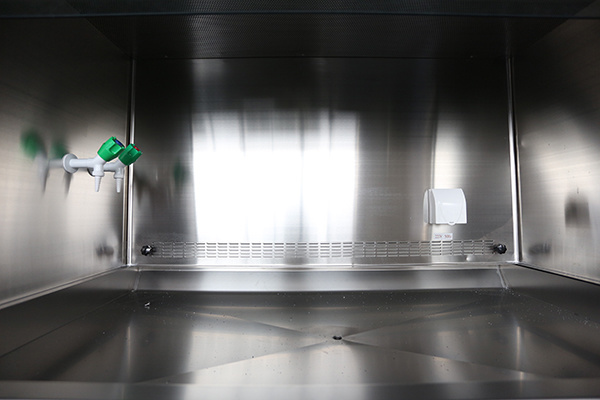

- The shell is made of high-quality cold-rolled steel plate and electrostatic sprayed; the three sides of the safety cabinet operating area adopts a stainless steel (SUS304) integrated structure, and the internal cleanable parts are treated with 8mm large round corners for easy cleaning;

- Unique internal cavity safety negative pressure design, air curtain isolation, to ensure no leakage under normal use, 70% gas circulation, 30% exhaust laminar flow, in line with YYⅡ biological safety cabinet standards;

- The integrated working table adopts a tray structure, which is easy to remove and clean. There is a liquid collecting tank under the operation table and a sewage valve under it;

- Biosafety cabinet is equipped with filter blocking alarm, blower overload alarm, working window opening limit alarm system;

- Integrated sliding safety sliding door, which can be positioned arbitrarily, is easy to operate, and can be completely closed for sterilization;

- Using ultra-high-efficiency air filter with a filtration efficiency of 99.999% (m particles). The filter membrane material is made of borosilicate glass fiber without partitions;

- The front window and germicidal lamp chain design: when the front window is raised, the germicidal lamp turns off;

- The bracket-type safety cabinet, the bracket and the upper box can be separated, which is convenient for transportation and positioning;

- Biosafety cabinet has the function of parameter memory and call recovery for protection due to power failure and data loss in crash state.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

Biosafety cabinets

biosafety cabinet distributor

biosafety cabinet class

biological safety cabinet

BSC for cleanroom

Previous:

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131