LVP(Large Volume Parenteral)Preparation System

LVP Preparation refers to sterile liquid preparation administered via intravenous infusion or body cavity irrigation, packaged in single-dose containers with a nominal volume ≥100ml. It is mainly used for body fluids/electrolytes replenishment, nutritional support or disease treatment.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

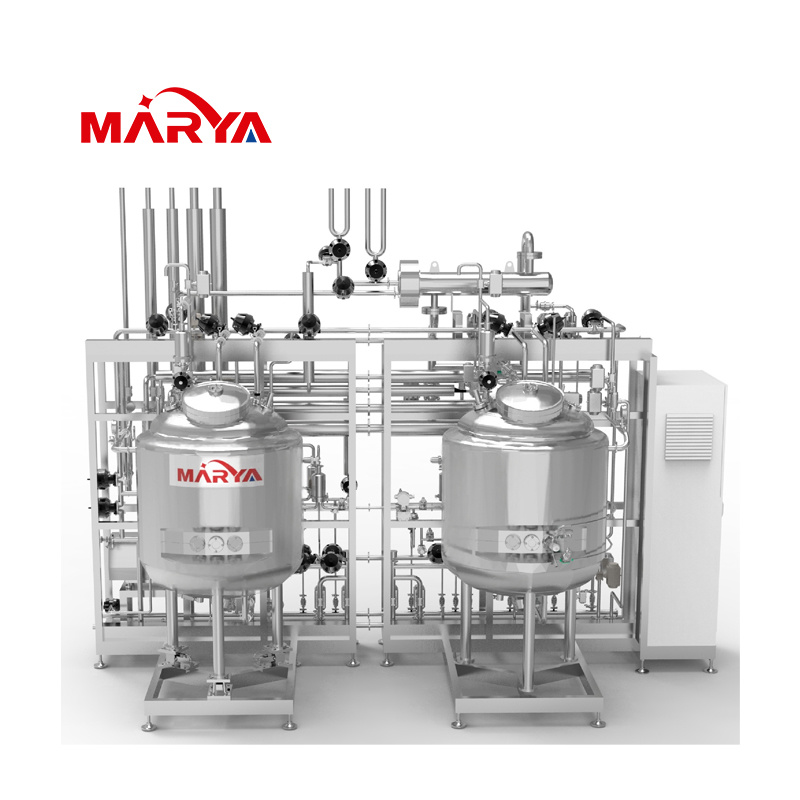

1. Large Volume Preparation Tanks: Made of 316L stainless steel with an insulation jacket, available in volumes ranging from hundreds to tens of thousands of liters.

2. Powerful Mixing System: Ensures highly uniform composition of large-volume liquids.

3. Fully Automatic Control System: One-touch operation enables recipe management, process recording, and remote monitoring.

4. CIP/SIP Functionality: Integrated in-process cleaning and sterilization, meeting GMP aseptic requirements and reducing labor. -

Performance Features:

1. The liquid mixing vessel incorporates a bottom-mounted magnetically driven agitator, ensuring leak-free operation with enhanced evenly mixing and efficiency.

2. The system adopts 3D modular design, offering a compact and aesthetically pleasing structure with space-saving configuration.

3. The system can achieve fully automated control of production, Cleaning-in-Place (CIP) and Sterilization-in-Place (SIP) operations.

4. Compliant computerized functions including flexible formula management, electronic signatures, electronic records and audit trails, etc.

5. Configurable with online analytical instrumentation (e.g., pH, O3, conductivity) to achieve controllable production of key process parameters.

6. Critical components utilize premium European/American brands, ensuring operational reliability and long-term performance stability. -

Vessel Volume

Vessel Design Pressure

Vessel Design temperature

Temperature control accuracy

Stirring speed

Weighing accuracy

1000/3000/5000/10000L

0.4Mpa

150℃

±1℃

0~400rpm

3‰

Other Parameters:

Tank Liner Material

316L / 904L / 2507 / Ti

Tank Jacket Material

304

Tank Insulation Layer

Rock wool/Aluminum silicate wool

Tank Surface Treatment

- Internal surface: Electropolished (Ra ≤0.4μm)

- External surface: Mechanically Polished (Ra ≤0.8μm)

Regulatory Compliance

NMPA GMP / EMA GMP / FDA GMP /PICs GMP / WHO GMP

-

Basic Functions

Optional Functions

CIP (Clean in place)

Vacuuming inside tank

SIP (Sanitize in Place)

Nitrogen protection

Hot water circulation

On-line integrity testing

Multi-level user access rights

PH automatic control

Recipe management

WFI instant cooling

Audit trail

Real-time data printing

Electronic record

Pipeline temperature control

-

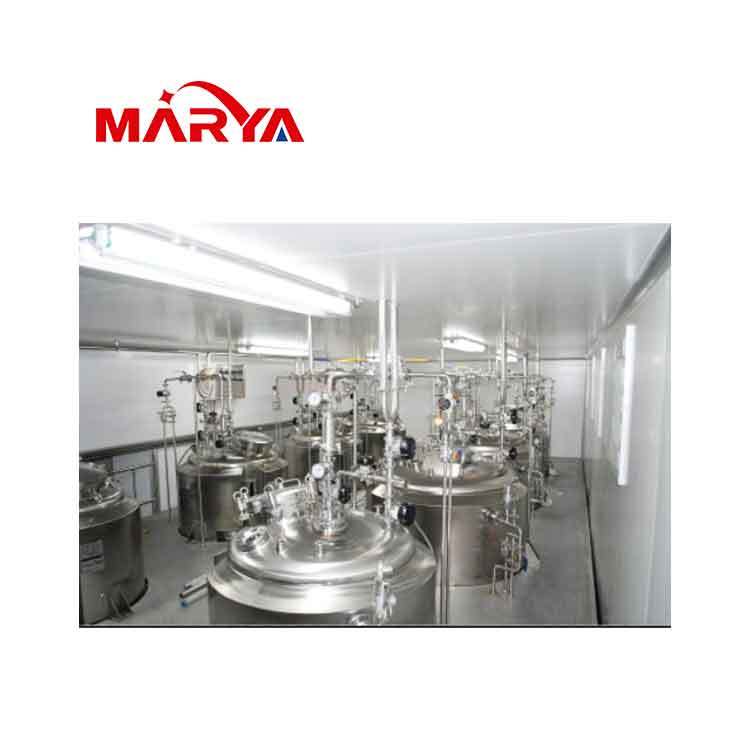

1. Large-volume infusion production: Used for bagged/bottled infusions such as saline and glucose injections, which are in high demand.

2. Biopharmaceutical culture medium preparation: Preparation of tons of cell culture media and buffers for large-scale bioreactors.

3. Oral liquid formulations: Large-scale mixing for products such as syrups and oral solutions.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

LVP(Large Volume Parenteral)Preparation System

sterile liquid preparation system

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131