-

Resource

-

-

Sterile Pharmaceutical Filling Line

-

Vial Filling Line

-

Syringe Filling Line

-

Cartridge Filling Line

-

RTU Container Filling Line

-

Ampoule Filling Line

View More -

-

Sterile Isolator System

View More -

Sterile Formulation System

-

SVP(Small Volume Parenteral)Preparation System

-

LVP(Large Volume Parenteral)Preparation System

-

CIP(Cleaning In Place)Station System

-

Stainless Vessel

View More -

-

Sterile Water Treatment System

-

Pharmaceutical Purified Water Generator

-

Pharmaceutical Water Distribution System

-

Pharmaceutical Water for Injection (WFI) Machine

-

Pharmaceutical Pure Steam Generator

View More -

-

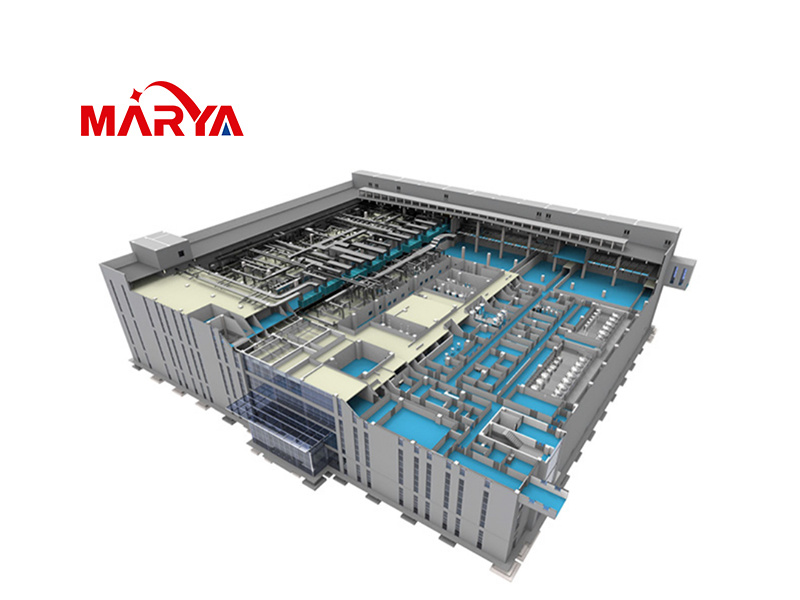

Cleanroom System

View More -

Other Pharmaceutical Machinery

-

Solid Medicine Production Line

-

IV Fluid Production Line

-

Oral Liquid Production Line

-

Packaging Machine

-

Other Pharmaceutical Machinery

View More -

-

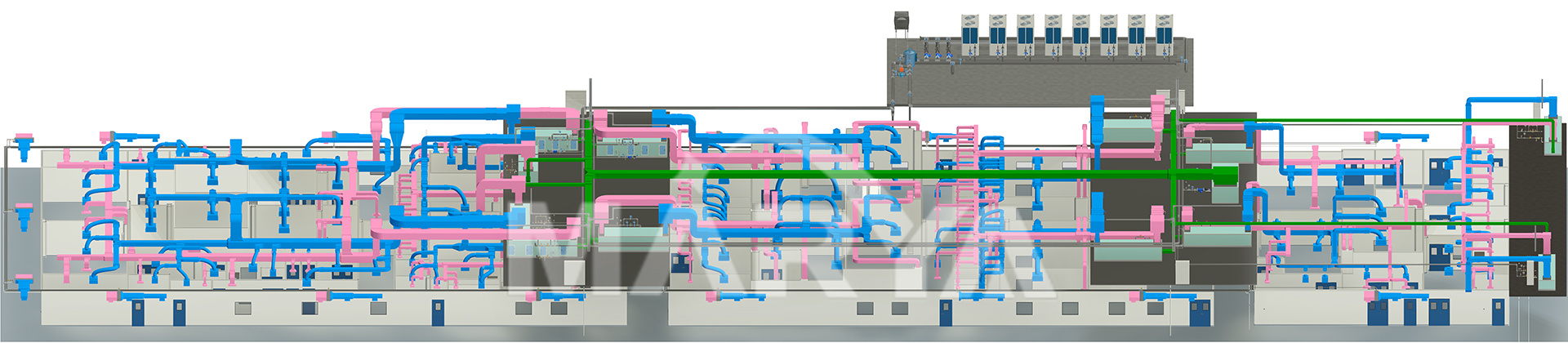

Cleanroom Solution

The one stop solution for cleanroom means blocking out and excluding all the pollutants such as microparticles, harmful air, bacteria, etc, within a certain space, reasonably distributing the overall plant structure in the area to meet the production process requirements. Cleanroom is a specially designed room, cleanroom solution needs to control the temperature, humidity, cleanliness, space height, room pressure, airflow velocity, airflow distribution, noise, vibration, electric distribution, lighting, static electricity, etc, in a cleanroom. No matter how the external air condition changes, the cleanroom's cleanliness, temperature and humidity, pressure, and other performance characteristics can all be maintained and ensure the original design and environmental protection requirements.

(1)The Decoration Materials in Cleanroom Solution

The maintenance structure mainly includes the following types:

Cleanroom roof/wall panel

Cleanroom doors and windows

Cleanroom floor

Connectors and accessories

Decorative arc

(2)The HVAC Engineering in Cleanroom Solution

The HVAC engineering mainly includes the following parts:

Air duct system: air supply, air return, fresh air, air exhaust ducts, terminals and control devices, etc.

Air conditioning system: including cold (hot) water units (including water pumps, cooling towers, etc.) (or air-cooled pipelines, etc.), pipelines, combined clean air-conditioning boxes (including mixed flow section, initial effect section, heating/cooling section, dehumidification section, pressurization section, medium-efficiency section, static pressure section, etc.)

Air filtration system: junior, medium, high efficiency filters, etc.

(3)Electrical System in Cleanroom Solution

The electrical system mainly includes the following parts:

Light and electric dispensing system: including clean lamps, sockets, wiring,etc;

Electric power distribution system: including equipment power distribution, electrical cabinets, lines, etc.

Weak current system: including video surveillance, access control system, telephone, etc.;

(4)Self-control System in Cleanroom Solution

The self-control system mainly includes the following parts:

BMS system: the air conditioning control system which includes cleanroom temperature control, temperature control, air volume and air pressure control, opening sequence and time control;

EMS system: the environmental control system which includes the control of environmental indicators such as dust particles, planktonic bacteria, etc;

Energy-saving and emission reduction control system: environmental protection and energy-saving control system;

(5)Other Cleaning Equipment

Includes ozone generator, negative pressure weighing room, air shower/cargo shower, pass box, environmental monitoring equipment and other purification auxiliary equipment;

CONTACT

Shanghai Office: NO211, North Fute Road, Pudong area, Shanghai, China, 200131

Changsha Office: Room 23069, Block 6, Forte Star Shine World, Yuhua District, Changsha, Hunan province

Factory 1: No. 7, Building 1, No. 326 Linyu Road, Yuelu District, Changsha, Hunan, China

Factory 2: No 555, Yupan Road, Weitang Town, Xiangcheng District, Suzhou, Jiangsu Province, China

Factory 3: 15-A, Venture Capital Industrial Square, Yanghe Road, Suzhou Industrial Park