Cleanroom panel

Marya is a cleanroom system provider specialized in project design, cleanroom material and equipment manufacturing, project management and validation. We can provide a variety of pharmaceutical cleanroom panels, and we are committed to becoming the customer's preferred clean room door manufacturers;

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Introduction of Cleanroom Panel

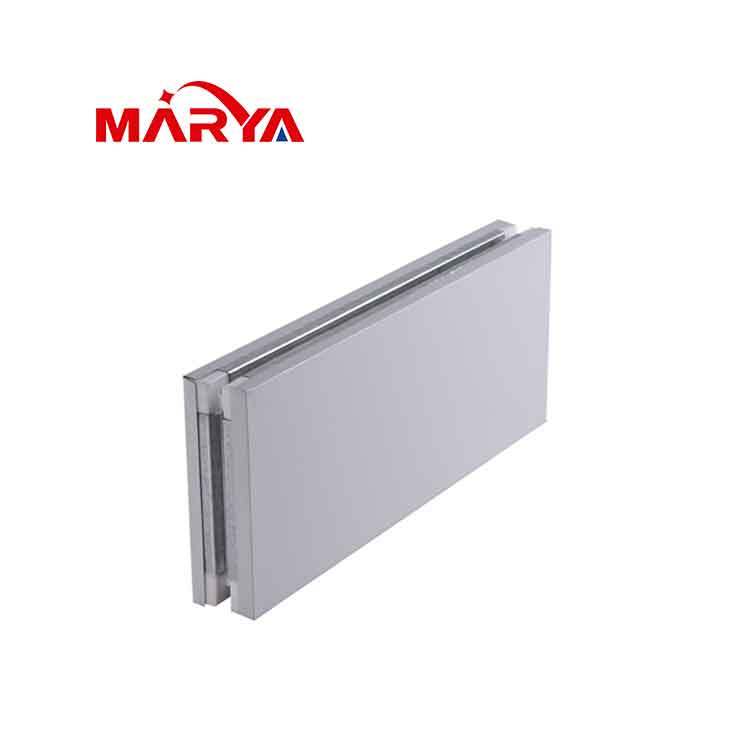

- Standard thickness :50 mm,75mm,100mm

- Panel material: color steel plate, stainless steel plate, HPL plate.

- Face panel thickness :0.5 mm、0.6mm、0.7mm、0.8mm.

- Filling material: glass magnesium, rock wool, rock wool with glass magnesium (rock wool with one side glass magnesium, rock wool with double side glass magnesiuml), aluminum honeycomb, paper honeycomb, EPS, PU, etc.

- Panel type: cleanroom sandwich panel, cleanroom wall panel and cleanroom ceiling panel.

According to the production method, cleanroom panel can be divided into hand made panel and machine made panel.

- Hand made panel: double-sided panel with high-grade polyester paint color coating, or stainless steel plate, with strong corrosion resistance. The core material adopts A grade fire proof, B grade flame retardant material (except paper honeycomb, EPS), it will not melt when burning, or produce high temperature decomposition drops. The handmade panel is a high grade fire proof building material decorative composite board in China at present. It has the characteristics of high strength, impact resistance, high seismic performance and convenient construction.

- Machine made panel: double-sided panel with high-grade polyester paint color coating, or galvanized steel plate, stainless steel plate, with strong decorative. The core material adopts A grade fire proof and B grade flame retardant material (except paper honeycomb), which will not melt when burning or produce high temperature decomposition drops. Through the mechanism production line pressing, the machine coating molding. It has the characteristics of fast processing speed, low construction cost, flexible size and other characteristics.

2. Characteristics

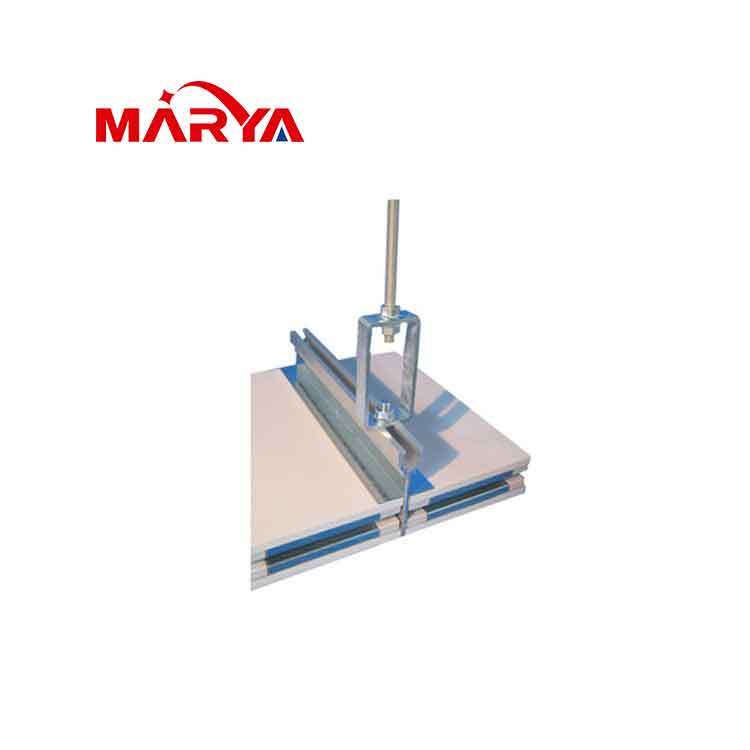

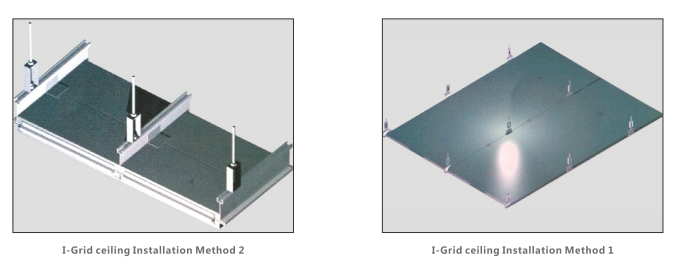

- Clean room panel standard installation and connection: panels are connected with built-in aluminum keel and PVC square tube, forming a continuous self-supporting structure; seams between two panels are sealed by silica gel. Roof is fixed by M-8 twisted steel and holder on the top of building.

- In order to enhance the strength of cleanroom roof, we can add gypsum or Mgo panel into color steel panel. People can walk on it and do various maintenance work. Materials weight need to higher than 100 kilogram.

- Cleanroom panel owns high quality surface materials, which have excellent performances, for example, chemical resistance, wear resistance, scratch resistance,etc.

- Cleanroom panel uses high quality thermal insulation materials as rockwool sandwich materials, and we seal the four edges of panels to avoid pollution due to leakage of sandwich material.

- The cleanroom panel can be pre-embedded according to the design needs to facilitate the passage of various pipelines, and can also be pre-embedded with reinforcing ribs to ensure the strength of the wall panel

- Cleanroom panel has a wall system that is quick and easy to install, flexible and multi-selectable components to meet various requirements, and all components of the wall system are connected smoothly and without protrusions.

3. Successful Cleanroom Project Case

We did a successful cleanroom project in Bangladesh, click on the following link to learn more details: Bangladesh-Cleanroom-Project

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

Cleanroom panel

Clean room panel supplier

Clean room panel Manufacturer

Clean Room panel price

Cleanroom Wall Panels

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131