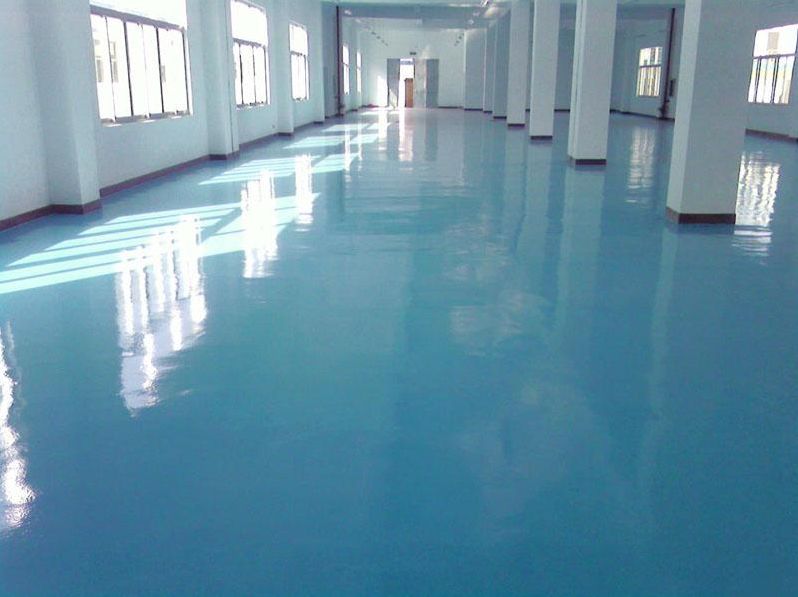

Cleanroom floor

According to the different needs of the occasion, the ground materials of different materials such as epoxy self-leveling, PVC coiled material and epoxy colored sand ground are used. And it can provide special ground materials with antistatic surface, and at the same time, it can be designed to distinguish different cleanliness levels in different colors in a project

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Introduction

- PVC floor characters:

- ①Safety and protection: The PVC flooring injection moulding passivation process makes the product surface free of air holes, so that dirt cannot penetrate deep inside. The antibacterial performance provides a permanent sterilisation and antibacterial treatment, preventing microorganisms from multiplying inside and outside the floor. PVC flooring uses a multi-layer structure, using a reasonable coefficient of friction, as well as clever dispersion of walking pressure and shock absorption performance, ensuring safe walking. The design of the wear-resistant layer structure at the top of the PVC flooring highlights the advantages of the multi-layer structure, containing a glass fibre reinforcement layer, ensuring constant dimensional stability and ensuring that the floor is not deformed or damaged. At the same time, the elastic cushioning of the foam layer prevents bruising due to falls. The practicality of the flooring and its excellent price/performance ratio make it particularly suitable for areas such as sterile laboratories, electronic clean rooms and pharmaceutical production halls.

- ②Maintenance convenience: PVC flooring of different qualities in the practical application of the product will reflect the obvious differences. To wear performance, for example, excellent wear quality can reduce the waxing, cleaning and other daily maintenance frequency, reducing the cycle of maintenance costs. PVC flooring surface attached to the polyurethane finish with water resistance, chemical resistance and dimensional stability, with a strong wear-resistant transparent PVC cover, greatly simplifies the use of the cycle of tedious maintenance steps, ideal for the use of factory decoration of clean rooms and other areas of the requirements It is ideal for areas such as factory fit-out cleanrooms.

- Epoxy Self leveling Floor: The surface is seamlessly painted, dust-free, wear-resistant, impermeable, resistant to heavy pressure, easy to clean, and has a good compressive and impact strength, so the durability and service life of the flooring is relatively long. The thickness of the middle layer of construction can make a partial repair of the unevenness of the base surface, ensuring that the finished surface has a good levelness, improving usability and aesthetics.

- Epoxy colored sand floor:

- ①Epoxy colored sand floor is a seamlessly integrated new type of composite decorative floor composed of colored quartz sand and epoxy resin. It can be freely matched through one or more colored quartz sands of different colors to form a variety of decorative colors and patterns.

- ②It has the advantages of elegant decorative texture, abrasion resistance, compression resistance, chemical resistance, non-slip, fireproof, and waterproof. The color can be adjusted freely, the color is bright, the decorative effect is good, the colored sand can form a beautiful surface; high cleanliness, no continuous contact marks; excellent wear resistance, acid and alkali resistance, and can inhibit the production of mold and bacteria; adequate surface flatness and roughness.

- ③The thickness of epoxy colored sand floor coating is generally 3.0mm and 5.0mm, and the effective service life is more than 10 years. Surface form of the floor includes bright type, non-slip type, rolling surface and self-flowing surface;

- ④Epoxy colored sand floor is mainly used for occasions that require abrasion resistance, strong impact resistance, and high-end decoration. With a certain floor style, it is especially suitable for airports, large shopping malls, exhibition halls, subways, electronic communications, medical and health, high-end commercial places, food production workshops, grease meat plants, offices and school laboratories, and some places which pay attention to external cleaning and durable.

2. Marterials Comparasion

No

Items

PVC

Epoxy self leveling floor

Epoxy colored sand floor

1

chemical stability

good

good

good

2

Surface density

good

good

good

3

Surface flatness

good

middling

middling

4

solvent resistance

good

bad

good

5

strength

middling

middling

good

6

Impact resistance

middling

good

good

7

difficulty of construction

easy

larger

big

8

Service life

7—10/years

shorter

10/years

9

maintainability

good

bad

bad

3. Successful Cleanroom Project Case

We did a successful cleanroom project in Malta, click on the following link to learn more details: Malta-Cleanroom-Project

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

clean room floor

pvc flooring

epoxy self leveling floor

epoxy colored sand floor

cleanroom floor

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131