HVAC Air Duct System

HVAC Air Duct System is the core of cleanroom operation; the design and installation of air ducts directly affect the quality of cleanroom engineering; reasonable design and installation of cleanroom air ducts can also save energy consumption and reduce pipe elbows for cleanroom operation, reducing unnecessary length of pipelines and reasonably designing the size of the pipelines, and can reasonably reduce the operating power loss of the combined air-conditioning unit and other issues.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Introduction

The specifications, size and form of the air outlets in the clean room meet the design requirements, the surface is flat and free of deformation, the self-contained adjustment part should be flexible, free from jams and looseness, and the spraying on the surface of the air outlets should be uniform in color, no color difference, and no scratches on the surface; when the duct cannot be connected by flange, the specifications, thickness and strength of the flange insert and spring clamp should be able to meet the design and use requirements; when damper, flexible short pipe, air hood and muffler are connected by flanges, the flange specifications should match the specifications of the duct flange.

The connection of the air duct should be firm and tight. The gasket material of the air duct flange should meet the requirements of the system function, and the thickness should not be less than 3mm, the gasket should not protrude into the pipe or protrude outside the flange; the installation of the flexible short pipe should be appropriate tightness and no distortion; the insertion of the air duct with the brick and concrete air duct should follow the direction of the airflow, and the insertion of the duct should be flush with the air duct surface, and should be sealed.

The joints of the air ducts should be intact and free of defects. The two planes of the air duct connection should be straight and without obvious distortion; the surrounding gaps of the spipot and socket air duct should be consistent, without obvious bending or wrinkles, and the internal sealant should be intact, and the external adhesive should be intact. The sealing tape should be adhered firmly and completely; a thin steel plate flange air duct interception, and the interval between the elastic inserts, spring clips or fastening bolts should not be greater than 150mm, and evenly distributed without looseness; open installed air duct should be horizontal and. The levelness deviation is 3‰, the total deviation should not be greater than 20mm. Open installed air duct is vertical, the vertical deviation is 2‰, and the total sheet output should not be greater than 20mm.

The position of the concealed air duct is correct and there is no obvious deviation; the spiral air duct should be installed without flange connection, and the circular air duct installed on the bracket should be provided with a bracket; when the air supply branch pipe and the main pipe are connected vertically, an air guide regulating device should be installed at the interface. Marya can provide cleanroom, cleanroom consulting, planning, design, construction, installation, transformation and other supporting services.

The regulating valve on the fresh air pipe is used to adjust the fresh air ratio; the electric closed valve is used to close the fresh air when the air conditioner stops running. The regulating valve on the return air manifold is used to adjust the return air ratio. The regulating valve on the air supply branch pipe is used to adjust the air supply of the clean room. The regulating valve on the return air branch pipe is used to regulate the positive pressure value in the clean room. The airtight regulating valve at the air outlet of the air conditioner is used to shut off the parallel air conditioner when it is out of operation, and it can also be used to adjust the total air supply volume of a single air conditioner. The regulating valve on the suction pipe section of the exhaust system is used to adjust the local exhaust air volume, and the check valve or electric closed valve on the exhaust pipe section is used to prevent outdoor air from backflowing.

There are three situations in which the air duct passes through the deformation joint: one is that there is a fire partition on both sides of the deformation joint, the other is that there is a fire partition on one side of the deformation joint, and the third is that there is no fire partition on both sides of the deformation joint. The norm is to install fire dampers on both sides according to the first case. The fire damper of the ventilation system is the main means to prevent the spread of fire.

From the consideration of not affecting the air purification effect and economy, the materials of the air ducts and accessories of the purifying air-conditioning system are determined according to the degree of purification of the conveyed air. Choose materials with high cleanliness that are not easy to produce dust, and choose materials with low cleanliness that produce less dust. The materials of the ducts and accessories of the exhaust system are determined by the corrosiveness of the conveying gas.

Set up pressure measuring holes or install differential pressure gauges before and after each level of air filter, so that it is easy to know the resistance change of each level of air filter at any time during operation, so as to clean or replace in time.

Non-combustible materials for air ducts and accessories refer to various metal plates, and non-combustible materials refer to glass fiber reinforced plastics with an oxygen index greater than or equal to 32. Non-combustible materials for air duct insulation and noise reduction refer to rock wool, glass wool, etc., and non-combustible materials refer to polyurethane (polystyrene) foams and rubber sponges with an oxygen index greater than or equal to 32. The insulation materials, gaskets, adhesives, etc. of the air ducts within 2000mm on each side of the fire partition wall and the electric heater within the range of 800mm before and after the electric heater should be made of non-combustible or non-combustible materials.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

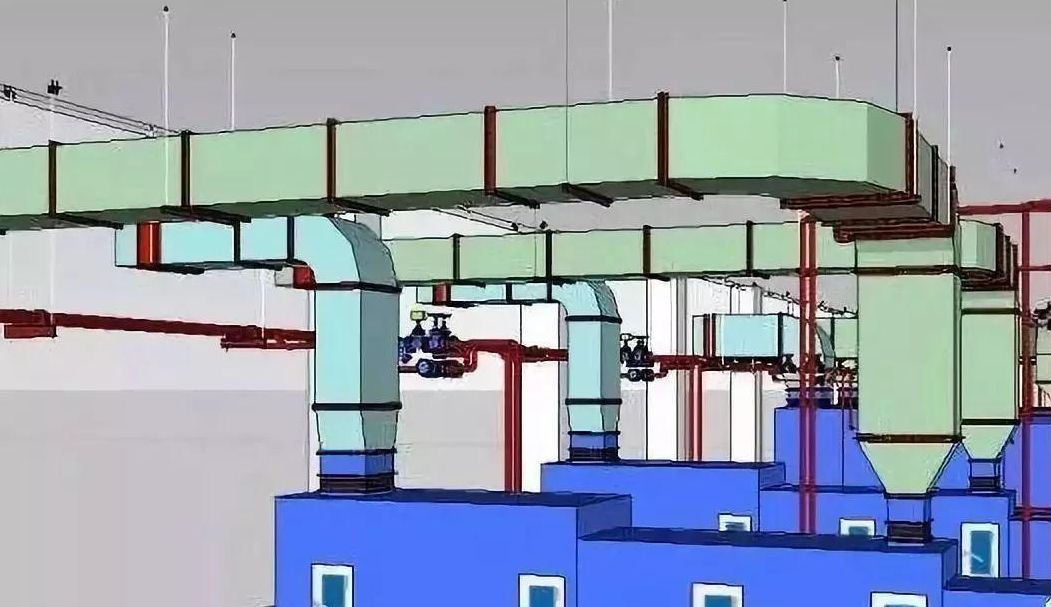

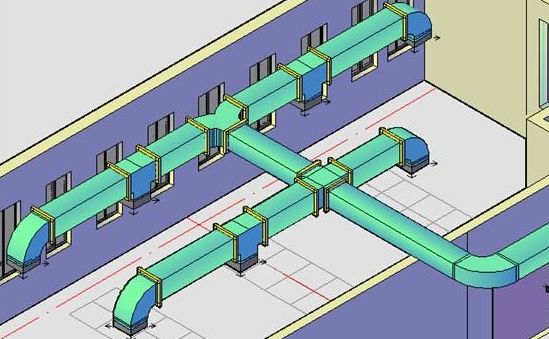

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

HVAC Air Duct System

air duct

hvac system

cleanroom pipeline engineering

Previous:

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131