Cleanroom air filtration system

The air filter is mainly used for clean air-conditioning system or air supply of purification equipment. According to the grade, it can be divided into primary filter (G1~G4), medium efficiency filter (M5~M6, F7~F9), high efficiency filter (E10~E12, H13~H14), ultra high efficiency filter (U15~U17) ). According to the structure, it can be divided into plate type, bag type, W type (box type W type), with partition, without partition, and tank without partition, etc.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

Generally, the primary filter can effectively filter out particles above 5um, and the medium-efficiency filter can effectively filter out particles above 1um, which can prevent particles from depositing on the surface of measuring elements such as temperature and humidity sensors, heat exchange elements, and air ducts, and improve system performance. At the same time, it protects the back-end high efficiency filter and extends its service life. High-efficiency filters are mostly used for terminal purification, and the gas is filtered directly into the cleanroom or clean space to maintain a clean environment to meet the requirements of use.

1. Air filter for general ventilation

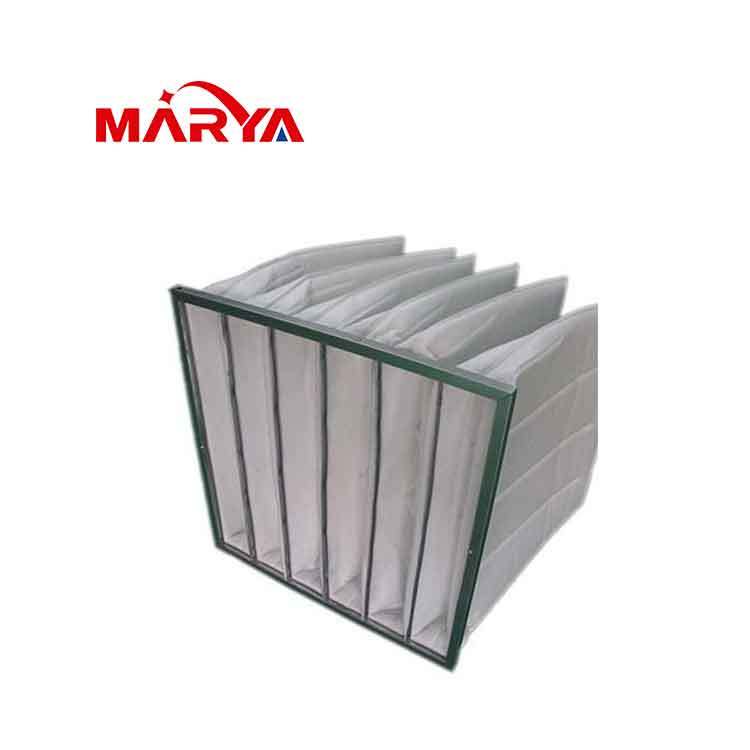

(1) Bag-type air filter

The primary effect bag-type air filter is mainly used to filter out dust particles ≥5μm in the air-conditioning system, protect the medium-efficiency filter, and extend its service life.

The medium-efficiency bag-type air filter is mainly used to filter out dust particles ≥1μm in the air-conditioning system, protect the subsequent sub-high-efficiency or high-efficiency filters, and extend their service life.

Characteristics of bag-type air filter

- Bag structure, increase the filter area

- A variety of welding program to meet the welding requirements of different filter materials

- The filter bag is welded in line, with high strength, preventing the risk of leakage;

- High consistency of filter bag parameters, improving product stability;

- Bag-type air filter frame material: galvanized sheet/aluminum profile;

- Bag-type air filter aluminum: PP/PET composite fiber;

- Operating conditions: the highest 100%RH, 60℃;

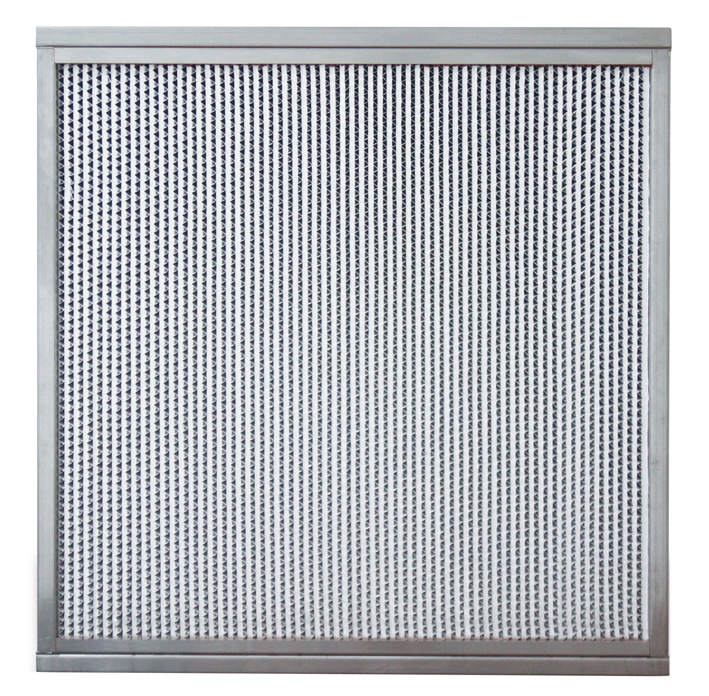

(2) Panel air filter

The panel air filter is mainly used to filter out dust particles above 5μm in the air conditioning system, protect the medium-efficiency filter, and extend its service life. The characteristics of the panel air filter are as follows:

- Small size and compact structure;

- Two forms of folding net and mother-child frame;

- Generally, it is the initial effect, but it can be the middle effect;

- Plate air filter frame material: galvanized sheet/aluminum profile/cardboard frame;

- Plate air filter aluminum: PP/PET composite fiber;

- Operating conditions: the highest 100%RH, 60℃;

(3) W-type air filter

The W-type air filter uses thinner filter paper without partitions to form multiple V-types, which effectively enlarges the filtering area and reduces the structural resistance of the filter. The air volume is large, the resistance is small, and the service life is long. The characteristics of the W-type air filter are as follows:

- Two types of box type and W type;

- Large filtering area, suitable for large air volume;

- F7-H14 various levels are optional;

- W-type air filter frame material: ABS/galvanized sheet/stainless steel/aluminum sheet;

- W-type air filter spacer: hot melt glue;

- W-type air filter filter paper: glass fiber filter paper;

- W-type air filter seal: PU sealing strip;

- Operating conditions: Max80%, 80℃;

2. Sub-high-efficiency/high-efficiency/ultra-high-efficiency filter

(1) Sub-high efficiency partition filter

Sub-high efficiency partition filters are used in clean rooms, commercial and industrial ventilation and air conditioning systems, and ventilation and air conditioning systems with high fire protection requirements or high ventilation temperatures.。

a. charateristic

- Aluminum partition, frame can be provided without flange, single flange, double flange, flange thickness 20mm;

- Using ultra-fine glass fiber filter paper;

- With partition design, high efficiency, low resistance and large dust holding capacity;

- Suitable for variable air volume system;

- Efficiency options: 85%@0.3μm(H10), 95%@0.3μm(H11), 99.5%@0.3μm(H12)(EN1822);

b. usage

- For clean rooms, commercial and industrial ventilation and air-conditioning systems;

- Ventilation and air-conditioning system in high humidity environment;

- Variable air volume ventilation and air-conditioning system;

- Ventilation and air-conditioning system with tight installation space;

- Ventilation and air conditioning systems with high fire protection requirements or high ventilation temperature;

- Widely used in clean rooms and other areas where air cleanliness is strictly required;

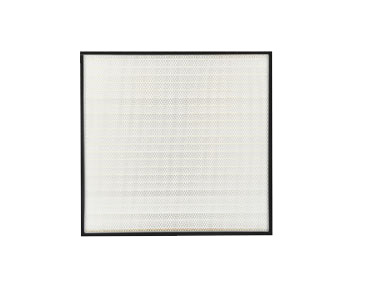

(2) Sub-high efficiency filter without partition

Sub-high-efficiency non-baffle filters are used in clean rooms, commercial and industrial ventilation and air conditioning systems, ventilation and air conditioning systems in high humidity environments, etc.

a. charateristic

- No partition design reduces operating costs;

- Wide application range, compact structure, saving storage space;

- Ultra-thin design, saving installation space;

- Efficiency options: 85%@0.3μm(H10), 95%@0.3μm(H11), 99.5%@0.3μm(H12)(EN1822);

b. usage

- For clean rooms, commercial and industrial ventilation and air-conditioning systems;

- Ventilation and air-conditioning system in high humidity environment;

- Variable air volume ventilation and air-conditioning system;

- Ventilation and air-conditioning system with tight installation space;

(3) High-efficiency/ultra-high-efficiency filter without partition

a. characteristic

- No partition design to reduce operating costs;

- Wide application range, compact structure, saving storage space;

- Ultra-thin design, saving installation space;

- Efficiency: 99.97%@0.3μm(H13), 99.99%@0.3μm(H14), 99.999%@0.3μm(U15)(EN1822);

b. usage:

- High temperature and variable air volume vent air conditioning system (medium-efficiency, sub-high-efficiency filter without clapboard);

- Used in the high-efficiency air supply outlet of the clean room of the pharmaceutical factory;

- Local purification equipment such as laminar flow hoods, clean benches, biological safety cabinets, pass box, etc.;

- Purification plant FFU products with high-efficiency filters

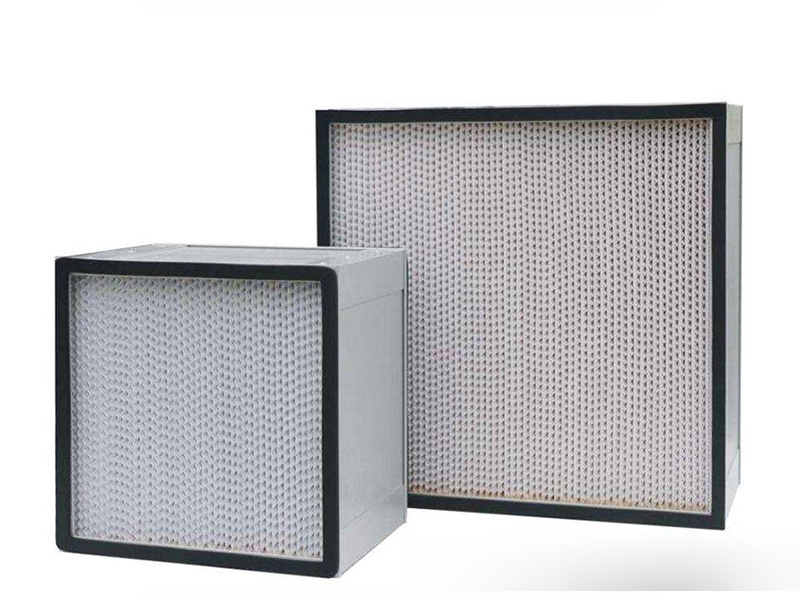

(4) High efficiency/ultra-high-efficiency filter with partition

a. characteristic:

The high-efficiency/ultra-high-efficiency separator filter adopts a separator-type design, and the corrugated separator can accurately maintain the distance between the pleats, and maximize the use of the filter material with the least resistance. 180 pleats on both sides of the filter material are folded into a wedge-shaped pleat layer. When the filter material is bent, there are two indentations to make it form a wedge-shaped box pleated layer at the end of the partition. The wedge-shaped box pleated layer can be Prevent damage to the filter material.b. usage:

It is mainly suitable for terminal filtration of various special clean rooms and various local purification equipment, such as clean bench laminar flow hood and other environmental air purification;

c. performance:

- Frame: aluminum alloy or galvanized iron and stainless steel frame;

- Filter material: ultra-fine glass fiber paper;

- Separation material: rubber paper or aluminum foil;

- EN779 level: H10, H11, H12, H13, H14;

- DIN 53438 flame retardant standard: F1;

- Final resistance: (recommended) 450Pa;

- Maximum air volume: 125% of the rated air volume;

- Temperature resistance: 80℃;

- Filter size: According to the actual requirements of the customer, the reference thickness of the aluminum profile; 120mm, 150mm, 220mm, 295mm;

- Limit size: width≤1220mm, length≥1220mm, thickness 50~300mm.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

HEPA filter

HVAC system

high efficiency filter

Cleanroom Air Filtration

clean room hepa filters

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131