Bottle capping and sealing machine

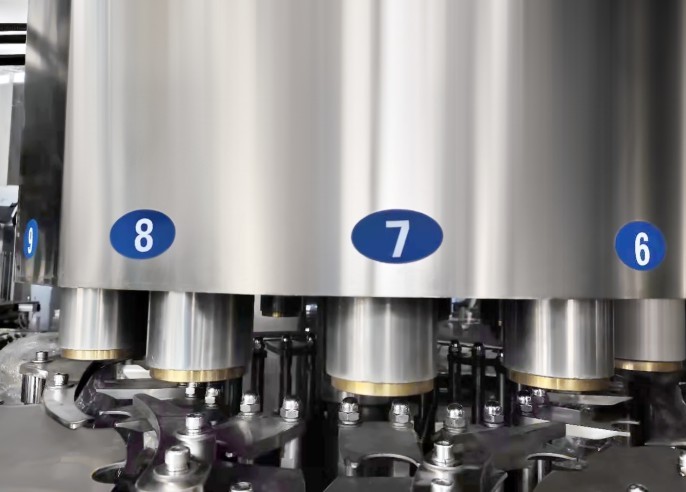

Capping and sealing machine is an automatic capping machine specially designed for the bottle production line of pharmaceutical and health care products, food, daily chemical and other industries. It adopts star-disk structure, which integrates capping, bottle feeding, capping and bottle discharging, and can precisely position and capping each bottle. There is no injury to bottles and caps during capping process, and it is suitable for various specifications of plastic bottle caps. Constant-torque capping mechanism can ensure that the screwing force of each capping head will automatically stop rotating after reaching a certain torque, and the torque can be easily adjusted.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Product Features

- The whole capping and sealing machine adopts PLC control and touch panel human-machine interface, which is convenient and intuitive to operate.

- This machine has high capping speed, high efficiency, smooth operation, wide range of use, and can be used with all kinds of bottling lines to meet GMP and FDA requirements.

- The structure of capping machine is divided into six major parts: lidding, lid management, lid hanging, lid pressing, bottle clamping and capping, each structure can be adjusted according to the container single.

- Complete machine with frequency control, PLC control and clear and easy to understand touch screen display.

- Constant torque capping head ensures that the capping head will stop rotating once the cap has reached the tightness requirement, which is suitable for products with high tightness requirement.

- Photoelectric sensor detection, lack of bottles or blocked bottles to suspend operations, automatic operation after recovery.

- Interchangeable capping heads to suit different cap locking and capping requirements.

- Structure tightening, electrical control and other parts are all sealed to avoid material affecting the service life of electrical components.

- Adopt embedded snap structure, easy to disassemble and clean, easy to use and maintain.

- No manned supervision during normal production, equipped with various automatic protection devices.

- The housing of the machine is made of stainless steel 304, which meets GMP requirements.

- Capping and sealing operation area is equipped with safety protection cover to provide more safety for the operator.

- Optional detection mechanism for screw cap defective products and no aluminum foil.

- Optional data network interface for data storage and reading management.

2. Technical parameters

- Production speed: 200 bottles/min.

- Suitable for bottle cap: φ15-120mm.

- Bottle diameter: ≥φ20-120mm.

- Bottle height: 30 - 200 mm.

- Air pressure: 0.4 - 0.6Mpa.

- Power supply power: 380V, 50HZ, 4.5KW.

- Dimension: 2000*1000*1720mm.

- Weight of the whole machine: 1500KG.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

Capping and sealing machine

capping machine

sealing machine

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131