Glove integrity testing system

Glove integrity tester is a special leak detection equipment to detect whether there is a glove leak. It is composed of the following parts: air pressure and pneumatic part, detection and control part, display part, box and glove interface part and so on.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

With the development of the industry, the isolation system requirements of the bio-pharmaceutical workshop are more and more strict, including the requirements of gloves, glove integrity testing machine is also more and more high, in addition to meet the requirements of FDA, GMP and other laws and regulations, computer online verification and real-time save has also become a trend. Our glove integrity tester not only conforms to the development trend of the industry, but also breaks through history, more accurate and faster.

1. Product features:

(1) Comply with FDA, GMP and other regulations and requirements of computer verification;

♦ Can implement wireless communication with the user equipment;

♦ Truly immutable data and real-time integration and production report, accord with computer validation;

♦ Built-in micro computer, can save enough capacity test data, and through the USB storage link;

♦ Administrator level 3 user permissions can be set;

♦ The built-in micro printer, may at any time to print the measured data;

(2) Design standards:

♦ Glove integrity tester is designed according to GB/T 25915.7-2010/ISO 14644-7:2004 requirements;

(3) Suggested usage time:

♦ When debugging;

♦ Before and after completion of work;

♦ After replacement of gloves and sleeve;

(4) Material:

All materials meet the requirements of medical grade and food grade;

(5) Appearance:

♦ Unique small appearance design, ergonomic operation handle;

(6) Group control of multiple devices:

♦ Can test at the same time up to 10 gloves;

♦ Can reach a single or multiple devices at the same time start and stop control, and add the alarm function;

(7) Stable performance:

♦ Key parts imported from Japan, safe and reliable;

♦ Have CE certification;

(8) Faster:

♦ The built-in battery charger, without external power supply;

♦ The built-in pump, without external compressed air;

(9) Unique airtight design:

♦ Shortening aerated time;

♦ The shortest test time was only about 5 minutes;

(10) Safe and sanitary storage:

♦ Safe and hygienic aluminum alloy box storage

(11) Usage:

♦ To test isolation system (barrier isolation system);

♦ Glove/sleeve leakage rate of proprietary equipment;

(12) Non-standard customization:

♦ According to user requirements for designing;

♦ Special customizable, guarantee the compatibility of different hand ring;2.Specifications and parameters:

Model

Length*height*thickness(mm)

Sealing ring size(feet)

WIFI function

Weight

KS-GITS01

250*330*132

Can be customized non-standard

No

12kg

KS-GITS01-W

250*330*132

Can be customized non-standard

Yes

12kg

3.Main technical parameters:

Name

Value

The maximum working pressure of glove cavity can be set(Pa)

2000

The maximum working pressure of the sealing ring can be set(MPa)

0.15

Pressure display resolution(Pa)

0.1

Dimensions(Length*height*thickness(mm)

308*338*95

Weight(kg)

4.5

Endurance(h)

4

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

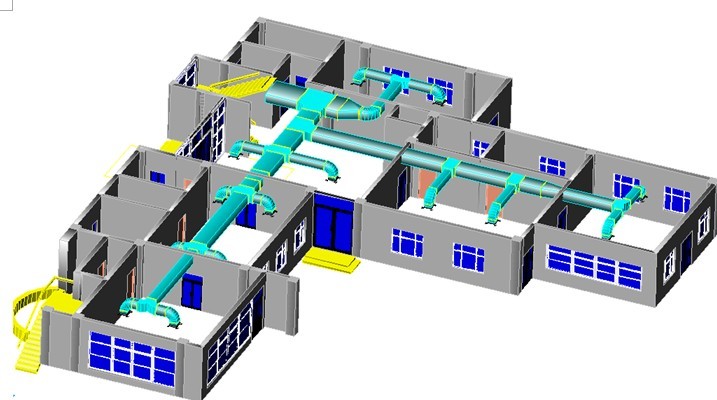

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

Glove integrity testing system

glove integrity testing machine

glove integrity tester

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131