Tablet Coating Machine

The tablet core continuously moves in a complex trajectory in the clean and airtight rotating drum of the coating machine, flipping smoothly and exchanging frequently. The coating medium stirred by constant temperature mixing tank is sprayed from spray gun to film core through peristaltic pump. At the same time, under action of hot wind and negative pressure, class 100000 clean hot wind supplied by hot air cabinet passes through core, and then discharged from air door through the bottom sieve hole, so that coating medium can be dried quickly on the surface of core to form a solid, compact and smooth surface film. The whole process is completed automatically under the control of PLC.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Introduction

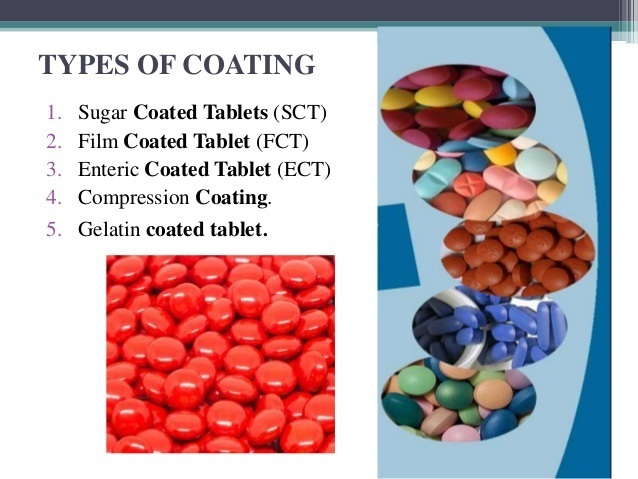

Coating machinery is widely used in pharmaceutical, food, biological products and other fields. it can make all kinds of organic film, water-soluble film and sugar coating for all kinds of tablets, pills, sweets.(The effect of slow and controlled release can be realized in the aspect of drugs.) The whole machine has the advantages of beautiful appearance, high efficiency, low energy consumption, small area and so on.

There is no dust and slurry spatter in the whole coating process, which improves working environment and reduces cross pollution of tablets. The process of tablet coating is simple, the coating time is greatly shortened and the production efficiency is improved.

2. Performance

- Drug-loading Rate: 5-600L

- A new type of microcomputer temperature and negative pressure module control system and touch screen graphic display and control are adopted, which has programmable function.

- Tablet coating machine can automatically adjust most of process parameters, such as flow rate, negative pressure, inlet air volume, exhaust air volume, temperature, speed, etc., so that the compilation of standard operation procedure (SOP) can be digitized. Different batches of goods can be produced with the same technical parameters, so that the difference between batches is close to zero.

- The coating machinery can be configured with data storage and printing functions: a variety of programs for automatic sugar coating and film coating can be modified at any time during operation; a printing device can be equipped according to customer requirements, so that process parameters and process flow of each batch of production can be truthfully recorded.

- Automatic in-place cleaning system can be configured: there is a high-pressure spray gun inside and outside coating pot, and a cleaning nozzle is provided at air outlet and hot-air outlet, which can rotate automatically in all directions, no dead corner, more convenient and easier cleaning.

- A professional customized spray gun can be used, which is strictly according to GMP and coating technology; all stainless steel design, easy to operate disassemble without any tools, flexibly control process requirements, prevent dripping and clogging, flow, angle and fan can be adjusted; uniform atomization, large spray surface, saving auxiliary materials

- The coating machine contains a mechanical device for coating in large container, and through its inherent mechanical adjustment, a small amount of plain tablets are coated in a large cylinder, which will not cause waste of auxiliary materials and greatly improve scope of use.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

Coating Machine

coating machinery

tablet coating machine

tablet coating machinery

Previous:

:Next

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131