Hot Air Circulating Drying Sterilizing Tunnel Oven for Ampoule Bottle

This machine is mainly used for drying and sterilizing for glass ampoules and other glass bottles like glass vials, oral liquid bottles, etc.

- Product Description

- Technical Features

- Technical Parameters

- Optional Systems

- Application Scenarios

- Video

-

1. Application

This machine is mainly used for drying and sterilizing for glass ampoules and other glass bottles like glass vials, oral liquid bottles, etc.

2. Introduction

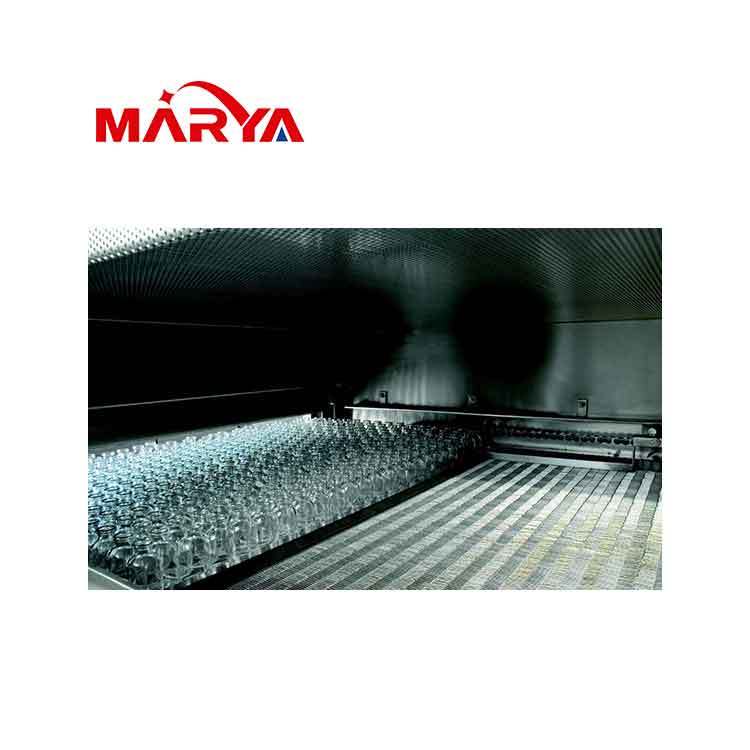

This Hot Air Circulating Drying Sterilizing Tunnel Oven consists of three sections : Pre-heating section, High temperature drying section and Cooling section.The Pre-heating section is composed of fan, dehumidifier fan and filter.

The High temperature drying section is composed of heat resistance fan, electrical heater, and high temperature filter, forming a circulation system inside the oven, ensures good temperature uniformity and high efficiency. The fan supplies heated air, passing through filter, circulated hot air continuously dries and sterilizes the bottles on the moving mesh belt(heating temperature can be adjustable from 50-350℃) .

The Cooling section is composed of fan, cooler, filter and air exhaust motor, forming a full circulation system to cool bottles, so that the bottle discharge port's temperature stays between 25~30℃.The whole process is under class 100 laminar flow protection with DOP test port and several temperature measuring ports. And this Sterilizing Tunnel Oven adopts PLC control, man-machine interface operation, the temperature is displayed by the temperature controller, set and recorded automatically, fully comply with GMP standards.

This machine can be used alone or combined with ultrasonic washing machine and filling capping machine to form a production line. The sterilizing speed of this Hot Air Circulating Drying Sterilizing Tunnel Oven is 100~600 bottles/min adjustable.

Years rich Industry Experience

Production Bases

Successful Projects in 60 Countries

Loyal Clientele

Invited to the Embassy of the United Republic of Tanzania in Guangzhou to discuss projects

Tanzanian Vice President Visits Marya Pharmaceutical EPC Project

NBA (Zimbabwe National Biotechnology Authority) conducts FAT at MARYA’s Factory

NOVO NORDISK client Visit

Clients visit the factory's liquid preparation system

Argentine client visits for FAT in MARYA

INTERESTED IN MARYA?

Get In Touch With Us.

We Will Be Happy To Discuss Our Solutions And Services With You.

Contact Now

Full-process Consulting Services

Whether you are preparing to build a new pharmaceutical factory, build a cleanroom that complies with local GMP regulations, or purchase pharmaceutical equipment to develop a new production line, whether it is a separate cleanroom or pharmaceutical machine project, or a one-stop solution, Marya's professional teams in the fields of pharmaceutical technical process, process equipment, decoration engineering, HVAC engineering, pipeline engineering, utility equipment, intelligent automatic control systems, project cost and other fields can provide you with full-process technical consulting services, and solve your needs one-on-one.

2D/3D Design Modeling Services

Marya project design team is composed of professional CAD and BIM engineers with more than 20 years of comprehensive industry experience and can provide you with comprehensive design services, including but not limited to process layout drawings, technical process charts, 3D models and animations, air conditioning system scheme design, construction drawing design, plant/pharmaceutical machine layout drawings, etc.

Machine Customization Services

Based on the individual needs of clients in different countries, Marya helps you clarify specific needs, match appropriate models, and customize one stop filling solutions for sterile small-volume preparations, large-volume injections, oral liquids/syrups, solid preparations, etc.

Validation Services (FAT/SAT)

Marya will appoint an engineer with rich project management experience as the person in charge, who will be fully responsible for project management and liaison work. After the equipment is manufactured, our engineers and the buyer's representatives will participate in the FAT test. After the equipment arrives at the buyer's site, it will be installed and debugged. After the equipment reaches optimal operation, the buyer will conduct SAT testing and inspection.

Key words:

Tunnel Oven

drying machine

ampoule drying machine

vial dry machine

tunnel drying oven

sterilizing drying machine

Contact MARYA Engineers to Claim Your Free GMP compliant Aseptic Pharmaceutical Production Line Solution

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT INFO

NO211, North Fute Road, Pudong area, Shanghai, China, 200131