-

Resource

-

-

Sterile Pharmaceutical Filling Line

-

Vial Filling Line

-

Syringe Filling Line

-

Cartridge Filling Line

-

RTU Container Filling Line

-

Ampoule Filling Line

View More -

-

Sterile Isolator System

View More -

Sterile Formulation System

-

SVP(Small Volume Parenteral)Preparation System

-

LVP(Large Volume Parenteral)Preparation System

-

CIP(Cleaning In Place)Station System

-

Stainless Vessel

View More -

-

Sterile Water Treatment System

-

Pharmaceutical Purified Water Generator

-

Pharmaceutical Water Distribution System

-

Pharmaceutical Water for Injection (WFI) Machine

-

Pharmaceutical Pure Steam Generator

View More -

-

Cleanroom System

View More -

Other Pharmaceutical Machinery

-

Solid Medicine Production Line

-

IV Fluid Production Line

-

Oral Liquid Production Line

-

Packaging Machine

-

Other Pharmaceutical Machinery

View More -

-

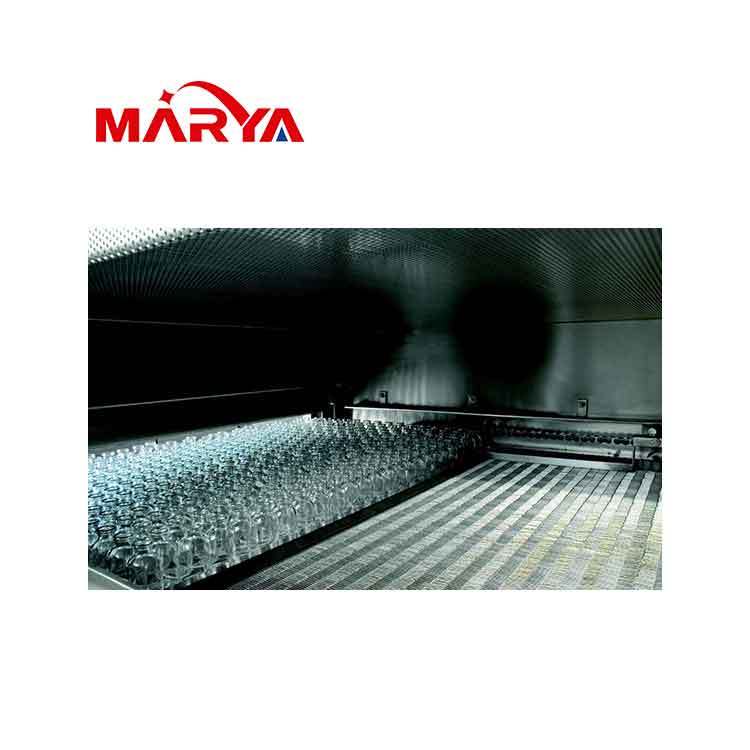

Hot Air Circulating Drying Sterilizing Tunnel Oven for Ampoule Bottle

This machine is mainly used for drying and sterilizing for glass ampoules and other glass bottles like glass vials, oral liquid bottles, etc.

Product Description

1. Application

This machine is mainly used for drying and sterilizing for glass ampoules and other glass bottles like glass vials, oral liquid bottles, etc.

2. Introduction

This Hot Air Circulating Drying Sterilizing Tunnel Oven consists of three sections : Pre-heating section, High temperature drying section and Cooling section.

The Pre-heating section is composed of fan, dehumidifier fan and filter.

The High temperature drying section is composed of heat resistance fan, electrical heater, and high temperature filter, forming a circulation system inside the oven, ensures good temperature uniformity and high efficiency. The fan supplies heated air, passing through filter, circulated hot air continuously dries and sterilizes the bottles on the moving mesh belt(heating temperature can be adjustable from 50-350℃) .

The Cooling section is composed of fan, cooler, filter and air exhaust motor, forming a full circulation system to cool bottles, so that the bottle discharge port's temperature stays between 25~30℃.

The whole process is under class 100 laminar flow protection with DOP test port and several temperature measuring ports. And this Sterilizing Tunnel Oven adopts PLC control, man-machine interface operation, the temperature is displayed by the temperature controller, set and recorded automatically, fully comply with GMP standards.

This machine can be used alone or combined with ultrasonic washing machine and filling capping machine to form a production line. The sterilizing speed of this Hot Air Circulating Drying Sterilizing Tunnel Oven is 100~600 bottles/min adjustable.

Keyword:

Tunnel Oven

drying machine

ampoule drying machine

vial dry machine

tunnel drying oven

sterilizing drying machine

Related Products

Products that maybe needed

Message

Looking for a worry-free, labor-saving, and cost-saving solution? Want to get product catalogs and price lists? Please fill out the form below or send an email and our professional team will contact you within 12 hours.

CONTACT

Shanghai Office: NO211, North Fute Road, Pudong area, Shanghai, China, 200131

Changsha Office: Room 23069, Block 6, Forte Star Shine World, Yuhua District, Changsha, Hunan province

Factory 1: Hunan Marya Technology Co., Ltd. Address: No. 7 Plant, SANY Industrial Park, No. 1, SANY Road, Changsha Pilot Free Trade Zone, Hunan Province, China, 410100

Factory 2: No 555, Yupan Road, Weitang Town, Xiangcheng District, Suzhou, Jiangsu Province, China

Factory 3: 15-A, Venture Capital Industrial Square, Yanghe Road, Suzhou Industrial Park